Customer Sectors

Waste Gas Treatment and Process Technology

Customer Sectors

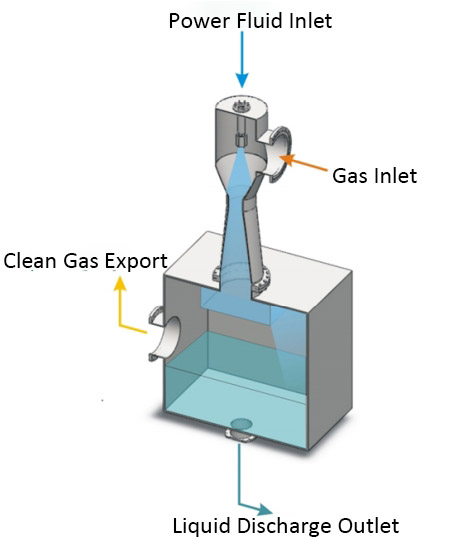

The High Energy Venturi Scrubber is one of the most important pieces of equipment capable of efficiently removing micron and submicron particles and harmful gases, and belongs to the category of wet scrubbers. Venturi is the standard choice for treating high temperature, high humidity exhaust flue gases containing a variety of pollutants such as acid gases because of the following advantages:

1: High safety when handling gases containing flammable and explosive substances.

2: Handles high moisture content gases with low maintenance costs.

3: Simple design for easy installation.

4: Cooling effect on hot gases.

5: Neutralizes acidic corrosive components in gases.

6: Removal efficiency is adjustable.

7: It also works well when the removed particles are sticky or highly viscous.

liquid-gas separator

Liquid-gas separator is one of our specialized equipments for gas treatment, which is mainly used with jet scrubber or high-energy venturi to Remove the dusty liquid droplets in the gas phase effectively. It is mainly used in the purification process of flue gas/exhaust gas treatment.

Packed tower is a commonly used mass and heat transfer equipment in chemical industry, which is widely used in the fields of oil refining, petrochemical industry, fine chemical industry, chemical fertilizer, pharmaceutical industry, environmental protection, etc. It is the preferred equipment for most of the processes such as cooling, absorption, distillation, purification, separation, desorption, gas extraction, extraction, chemical exchange, washing, and so on.

Cyclone Washing Tower:

Cyclone scrubber tower is a kind of packing tower equipment developed by our company which combines separator and scrubber tower into one, and is suitable for the process with less solid particles content. Compared with two separate tower equipment, cyclone scrubber tower occupies less space and has smaller investment.

The use of wet scrubbers to control air pollution has been widely recognized throughout the industry.

Injector-Venturi wet scrubbers offer many advantages over many traditional single-purpose units. Particle collectors such as cyclones and electrostatic precipitators do not effectively absorb gases or remove odors. Fabric filters are not designed to handle gas streams with high moisture content and are often subject to highly corrosive gases. Catalytic incinerators can be rapidly poisoned by certain organic wastes.

On the other hand, the Injector-Venturi Gas Scrubber is very effective in removing harmful gases, particles, odors, smoke and ash from the air stream. Particulate contaminants are removed by the high velocity spray impact of the scrubbing fluid. Gases and odors are removed by absorption and/or chemical reaction between the gas and the scrubbing solution. When properly matched to the application, these scrubbers are by their very nature better able to cope with the high temperatures and corrosive conditions often encountered.

This page is translated by AI from our company's Chinese official website. If you have any questions, please contact us